ESG

관련링크

본문

On June 20, 2024, CTR Eco-Forging signed an agreement with the Korea Environment Corporation for the Smart Eco-Factory Construction Project. As part of its ESG management, CTR Eco-Forging launched this project to minimize environmental pollutants generated during the manufacturing process and reduce energy usage, aiming to create a green, low-carbon factory.

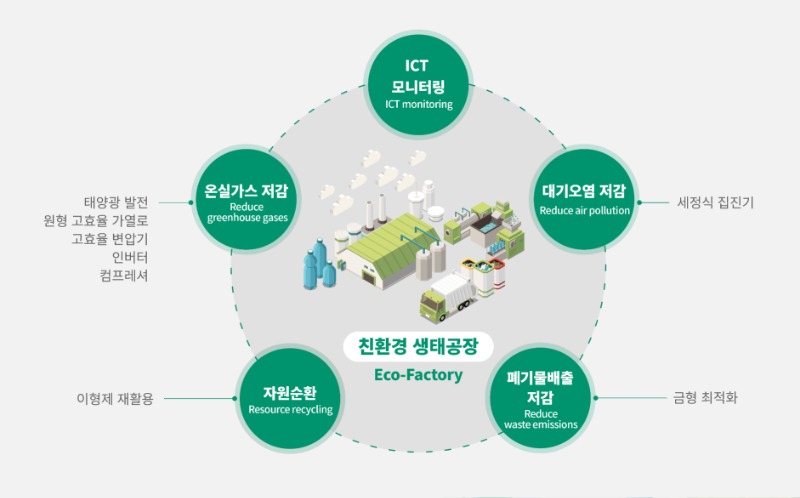

The Smart Eco-Factory Construction Project supports manufacturing plants in reducing greenhouse gases, minimizing pollutants, and enhancing the efficiency of energy and resource usage. This initiative helps small and medium-sized enterprises transition to eco-friendly factories.

Details of CTR EcoForging Smart Eco-Factory Construction Project

Q: How did CTR Eco-Forging prepare for the Smart Eco-Factory Construction Project?

CTR Eco-Forging began preparing for the Smart Eco-Factory Construction Project in 2023 by initiating eco-friendly management (ESG) consulting. For approximately nine months, we continuously worked with consulting firms to identify items and closely coordinated with equipment partners.

After submitting a business plan that included the project's goals, growth potential, necessity, implementation plan, and expected benefits, we were selected through a document review. Subsequently, through on-site inspections and a business plan presentation, the project's viability was recognized, leading to the final agreement.

Q: What are the benefits of proceeding with the Smart Eco-Factory Project?

While preparing for the Smart Eco-Factory Support Project, we planned to invest 1.49 billion KRW in the project, regardless of the selection outcome. However, being selected for this project allowed us to receive 50% of the budget as government support, resulting in reduced investment costs and depreciation expenses. Additionally, once the equipment operates at full capacity, we expect to save 530 million KRW annually in environmental costs such as electricity and waste disposal.

*Depreciation expense: The allocation of the cost of a fixed asset over its useful life to different accounting periods.

Q: What are the expected future benefits?

Through this project, CTR Eco-Forging will introduce various new equipment!

The main equipment includes a solar power generation system, an aluminum billet heating furnace, forging molds, a hybrid transformer, a press drive inverter, an inverter compressor, a compressor dryer, a dust collector, a release agent recycling device, and an ICT monitoring system.

With these installations, we aim to reduce greenhouse gas emissions by 358 tons annually and recycle 27 tons of resources. If the expected effects occur at 100%, we anticipate securing additional profits equivalent to approximately 0.5% of the annual revenue.

CTR Eco-Forging Panoramic Photo

Since the ESG management declaration ceremony in April 2023, CTR Group has been engaged in various ESG activities. These include establishing a renewable energy subsidiary, setting up and operating an integrated ESG committee, and participating in the Carbon Disclosure Project (CDP), all aiming to foster sustainable growth as a reliable partner for a secure future.

Aligned with these goals, the Smart Eco-Factory project aims to reduce emissions and energy consumption, optimize equipment operation efficiency, and promote resource recycling. This initiative is expected to boost revenue, create jobs, and contribute to the revitalization of the local economy.

The efforts of many members of CTR Eco-Forging have made this agreement possible. We extend our gratitude and support to all who will continue to work hard towards establishing ten smart eco-factory facilities in the future.