글로벌 미디어

관련링크

본문

Hello everyone. I'm Dong Yoon LEE at CTR design team.

I mainly work on design and development of chassis parts including the development of new specifications.

Today, I would like to introduce Ball Joints of chassis parts, particularly injection-type ball joints,

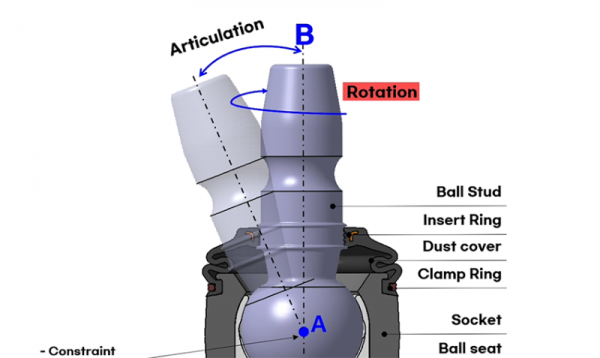

Ball Joint is a part used in the suspension system of car. There are various types of Ball Joint depending on the relative coupling method, the load support, and the manufacturing process and it has two main functions.

First, it is to maintain the connection between the wheel and the body by adjusting the angle that changes according to the movement of the vehicle.

Second, it absorbs shock or vibration from the road to improve ride comfort.

The product I'm introducing today is the injection type ball joint

The injection type Ball Joint has been developed with a focus on lightweight design to align with the trends of improving fuel efficiency and environmentally friendly vehicles, such as electric vehicles.

The key features of the injection type ball joint are as follows.

First, in the case of the caulking type, the clearances and torque distribution is large according to the inner parts and caulking process. but injection type has minimized torque distribution and clearances. This allows for higher durability compared to the caulking type.

Second, by using plastic materials, the weight can be reduced by about 5% compared to caulking TYPE.

Currently, injection type Ball Joint has been produced to one of the global OEM.

So far, the performance is on the good condition as existing caulking type, and the customer is highly satisfied with the performance.

In the future, we plan to further enhance the advantages of the injection type Ball Joint for more cost reduction and lightweight.

Thank you for the opportunity to introduce the injection type Ball Joint, and hope you are interested in the injection type Ball Joint.

Thank you.