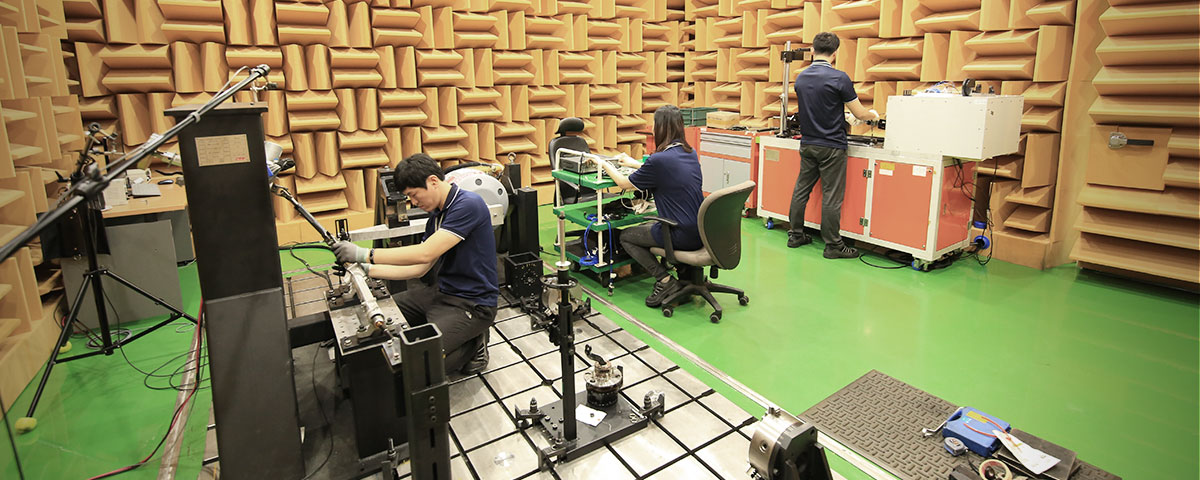

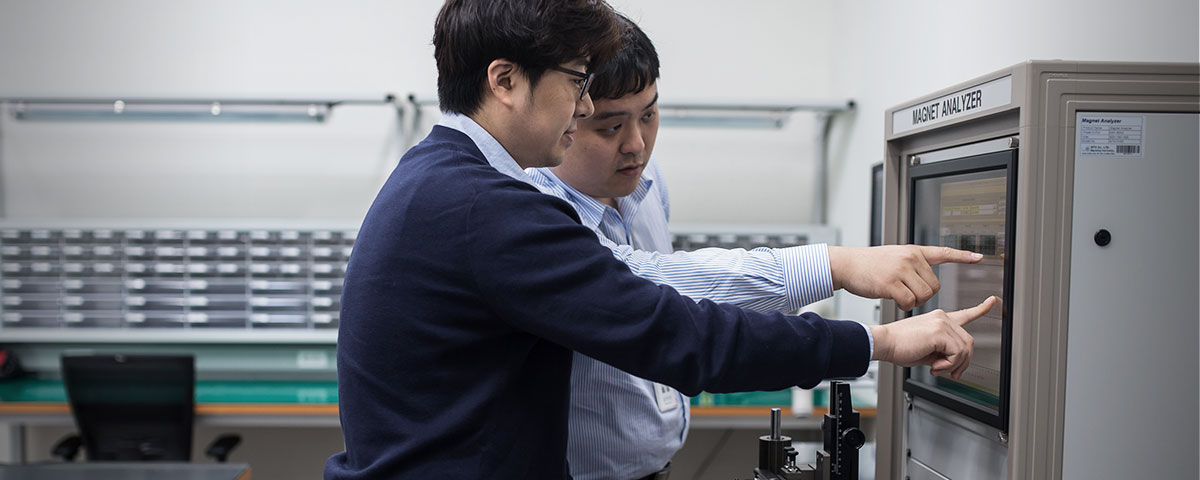

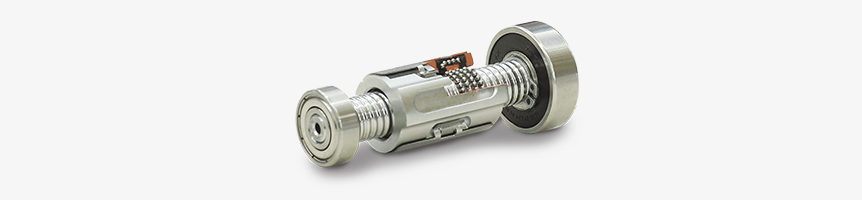

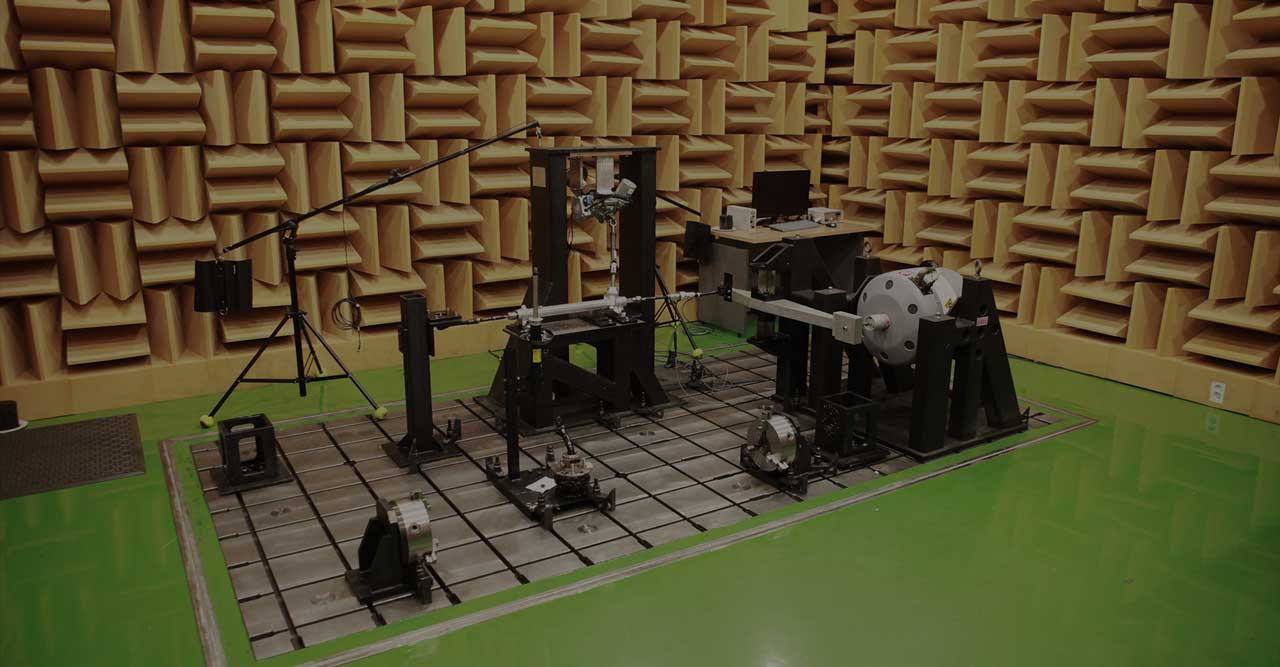

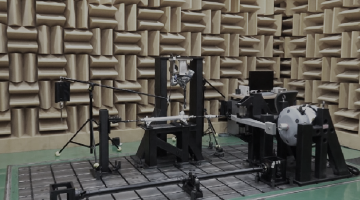

1990년 독자적인 기술 경쟁력을 갖추기 위해 설립된 CTR 기술연구소는 현재 120여 명에 달하는 전문 연구 인력을 보유하여최고의 기술을 향해 끊임없이 전진하고 있습니다. 기초 소재 연구와 다양한 해석 기법으로 신소재를 적용하여 제품 경량화에 기여하고 있으며,실차 조건에 최적화된 다양한 시험장비로 테스트하여 완벽한 제품을 개발하기 위해 노력하고 있습니다. New mobility의 트렌드를신속하게 파악하고 연구하여 미래를 선도하는 핵심기업이 되기 위해 앞으로도 도전과 혁신을 멈추지 않을 것입니다.

-

설계, 개발능력 향상

-

원가경쟁력 확보

-

전략 신기술 개발

-

전문인력 확보